Reference Data.

Incorporated.Natomas Consolidated of California

1908 - 1914

Natomas Company of California

1914 - 1928

Natomas Company

1928 - 1984

Locomotives

#1 - Vulcan c/n 1136, 7/1907 0-4-0st

36" gauge, 7x12 24" dr. Folsom Rock Company -Natomas Construction Co No 1

#2 - Vulcan c/n 1288, 3/1909 0-4-0st

36" gauge, 10x14 30,000lbs Natomas Construction Co No 2, ship to Fairoaks Bridge, CA, later to Coast Rock & Gravel Co, Herron

Freight Equipment

Approx. 30 dump cars, unknown builder.

The Natomas Consolidated Company.

By Andrew Brandon.B y the end of the 19th century, placer mining along the American river was no longer economically viable on a small scale. Remaining gold bearing gravel in the river channel was at a level too deep to be economically recovered through traditional methods. Dredging the riverbed became the next step in mining. The first dredge in the Sacramento area was a bucket-line dredge, brought to the American river in 1899 by the Colorado-Pacific Gold Dredging Company to work the river around Mississippi Bar.

In 1899 Robert G. Hanford came to California from Idaho where he had supervised several dredge mining operations. He started the Colorado-Pacific Gold Dredging Company on 200 acres of land purchased from Clarke and Cox of Sacramento. The Syndicate Dredging Company hired Hanford to supervise their dredge operation in the American River District.1 Over the next few years the financiers reduced their support for the project. Hanford sued the company after they failed to pay him for his services as manager and reimbursement for operating costs.2

Hanford was involved in other projects. In 1901 acquired the San Francisco and San Mateo Electric Railway, and gained controlling interest in the Sutter Street and Market Street Railroads in San Francisco. In November 1901 he sold his interest in these companies to the Boston Syndicate for $26,000,00. The new owners merged the railroads into the United Railroads of San Francisco in 1902.

Hanford returned to Sacramento and turned his attention toward dredging the Folsom district. There he incorporated the Folsom Development Company in 1903, followed by the Folsom Rock Company, a subsidiary. The Folsom Development Company would manage reclaimed land development, while the Folsom Rock Company would engage in dredging the American river.

In 1905 the Folsom Rock Co. purchased the first Reclamation dredger in California. This design differed from standard designs by sorting the fine materials from the coarse and spreading them evenly. As designed, the dredge would distribute the coarse closer to the dredge and the fine material further away allowing this material to slope towards the boat, filling the area between the cobbles. This process created land suitable for development as farms and orchards once it had been leveled.

In late September 1906 R. G. Hanford incorporated the Natomas Development Company and purchased the Natomas Vineyard Company.3 The purchase included some 1700 acres to the south of Folsom and the Natomas Ditch system which carried water from Salmon Falls to Folsom and the Natomas farm lands. Control of of the ditch system was given to the Folsom Development Company. Later that year Hanford was able to convince local voters to create a new reclaimation district on the American river. On December 29th, the American Reclamation District was created, giving the Natomas Consolidated some 56,000 acres of land to work and reclaim.

Debris from hydraulic and dredge mining operations was a constant problem for farmers in the central valley. The stacked tailings from dredges were a nuisance and left land along the river unusable. R. G. Hanford spent two years researching and developing a rock crusher to be built along the Southern Pacific's Placerville Branch at Dredge, later renamed Natoma. Crusher No. 1 commenced operation on August 1907. This crusher sorted the stone into different grades, from cobbles for residential use, to fine gravel for road grading. The Southern Pacific established a depot there in November 1908.

The Natomas Consolidated Company was formed on January 1st 1909 from the consolidation of the Folsom Development Company, Natomas Development Company, El Dorado Gold Dredging Company and the Natomas Vineyard Company. Company directors: Eugene de Sabla, President. W. P. Hammon VP, Louis Sloss VP, F. W. Griffin VP, A.E. Boynton Treasurer, Newton Cleveland general manager. This reduced the number of companies working the Folsom District down to just two: the Natomas Consolidated and Ashburton Mining Company. 34

The company built a 36” gauge railroad to serve Crusher No. 1. The railroad operated over temporary track to bring the dredge tailings to the crusher. Trains of seven cars were loaded by steam shovel near the river and returned to the crusher where their loads were emptied. As constructed the crusher used an incline to haul each car up for dumping. This arrangement was slow and the arrangement was replaced with a ground level bin and conveyor system allowing for multiple cars to be dumped at once. In this new configuration it took 8 minutes to fill each train and an additional 7 minutes to unload at the crusher. From there it took 10 minutes to fill a 40-ton standard gauge car. The plant had the capability to fill two standard gauge cars of the same graded stone simultaneously.

In the first year of operation the company’s seven dredges worked 321.48 acres of land and 13,975,185 cu yards of gravel. In 1909 the Natomas Consolidated also took over the holdings of the Cherokee Gold Dredging Company, and the Feather River Exploration Company operations near Oroville. These operations gave the company and addtiona 1,364 acres. The Natomas Consolidated was then said to be the second largest dredging company in the state.

Along the feather river, the company employed the clam-shell dredge “Hercules” to build levees around Verona. Shortly afterward the company constructed a plant in Oroville (Crusher No. 3). Capable of processing 1500 tons per day. The new rock crusher (No. 3) near the Swayne Lumber Company mill in Oroville. Unlike Crusher No 1 and the later No 2., this plant utilized a standard gauge railroad to move dredge tailings in to the crusher. These cars were handled by the Northern Electric Railway (later Sacramento Northern).

Crusher No. 1 was never completed to operated at planned capacity, instead the company opted to build a larger facility to the east at Fair Oaks Station. Rock Crusher No. 2, the largest they owned, began operation in July 1909.

Clean gravel is dumped into bins and carried by a 380' conveyor belt to a revolving screen. Dirty or wet gravel is passed through a revolving screen, 6' in diameter and 3-' long with 1/4" holes, where it is washed; Everything over 1/4" passing to the conveyor belt with the dry clean gravel. The fine slickens is washed down a flume and distributed over the leveled land. The gravel is then carried to a screen 5' in diameter by 30' long with 2 1/2" preforations. Everything over 2 1/2" in diameter is crushed, the dust washed out, and run through sizers for the following: 1/8" x 1/2" x 1". 1 1/2" x 2 1/2". dust x 3/8". The balance of the material is stored as washed gravel. The following crushers are used : One 42" x 26" jaw crusher, 7-36" x 10" jaw crushers and 1-48" Symons disc crusher. A conveyor belt passes under all of the discharge belts and any mixture of sized rock can be obtained. The railroads are arranged under the conveyor belts so that the cars run from the yard by gravity. The production of the plant is about 1500 tons of crushed rock and 500 tons of washed gravel in 10 hours. Crusher No. 2 designed by Western Engineering & Construction Company. Has a capacity of 1500 tons crushed rock per 10 hour day.

source.

While the primary product of the rock crusher was gravel and macadam for roads and highways, including the Sacramento to Folsom Road. The company also sold fine cobble for architectural purposes. These cobble were was sorted from the plant and sold throughout the state. Many structures in the Sacramento area were constructed with this cobble. The Northern Electric Railway constructed their Bungalo style depots with Natomas Consolidated cobbles.

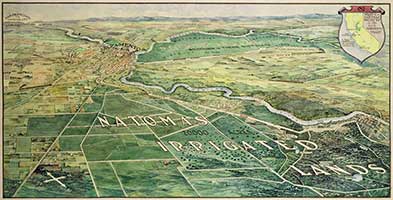

Aerial view of Natomas Company lands, 1915.

Among the other goals of the company was reclamation of the lands they dredged. Shortly after the first dredges arrived in the area, J. H. Legget of Oroville discovered the remaining tailing mounds were found rich in clay and volcanic ash. The combination of this soil and the surrounding stone resulted in soil which retained moisture nearly 2 feet below the surface, even in the heat of summer. Further experiments found the land suitable for farming when it was cleared and leveled. The Natomas Consolidated planted several experimental farms, including a grove of Blue Gum Eucalyptus in Oroville and an Orange Grove near Natoma. Land to the east of Natoma was leased as experimental orchards, the land west was used for Wheat.

In 1911 the San Francisco Call reported that the company had just put Dredge #8 into operation, at the time it was the largest in the world. The voters of Sacramento and Sutter counties voted to create a new reclamation district #1000, which included lands along the eastern short Sacramento river as far east as the Northern Electric right of way, and north to Pleasant Grove. The company shipped 4,441 cars of stone from Crusher No. 1 in 1912. A second reclamation district, #1001 was created soon afterward. This district included the lands immediately north of district #1000 as far north as the Bear river.

Rock Crusher No. 1 ceased operation in June 1913, but the shipment of rock on hand continued through March 1914. WWI took its toll on the company and that December 24th the company reorganized as the Natomas Company of California after missing bond payments. At that time the rock crushing plant at Oroville was producing 3000 tons per day.

In March 1915 the Southern Pacific Railroad applied for permission to close their the depot at Natoma. The SP was allowed to close the agent's office on April 10, but was required to keep the waiting room open for an additional 6 months. The Natomas Consolidated Company took over the handling of freight to Natomas, though the SP agent at Folsom was to be assigned to insect freight at the Natomas warehouse when necessary.5 The company put their first bulldozers to work leveling the reclaimed lands in 1917 utilizing specialized blades designed by the company. The company’s fleet of dredges were all electric by 1919.6

In April 1920 the operations of the rock crushing plants in Fair Oaks and Oroville were leased to the Coast Rock & Gravel Company. Coast Rock & Gravel was also the management of the California Building Material Company plants at Niles and Eliot, in addition to Granite Rock’s plant at Logan.7

Much of the reclaimed land remained unsold and the company was forced to reorganized as the Natomas Company of California on November 13, 1928. The new company lowered the price of the land below the appraised value. Land sales increased rapidly so that only 3,000 acres remained to be sold by 1948.

Despite their intent of reclaiming the land for agricultural use, only 0.2% of the land in Sacramento County was sold for this purpose. The remaining land would be sold for industrial purposes. Aerojet purchased 7,300 acres of dredged lands in 1951. All available land was sold out in districts 1000 and 1001 in 1955. In 1956 Aerojet purchased an additional 4,200 acres, 11,500. At that time, the Natomas Company's involvement in RD 1000 ended, and they turned over control of the district to the landowners. The Natomas Company merged with APL Associates Inc. later in 1956.

In 1961 the Natomas Company proposed the American River Parkway to Sacramento County Parks & Recreation. 1000 acres of land would be donated and they serve as hiking trails today. On February 12, 1962 the last dredge in Folsom, Natoma No. 6, was shut down. In 1966 the state of California acquired 1800 acres of Natomas lands held in Butte county for the construction of Oroville Dam. At the end of dredge operations, the Folsom district had produced $125,000,000 in gold.

At an unknown date the company switched to trucks instead of the narrow gauge railroad to haul material to Crusher No. 2. Fair Oaks plant later operated by the Pacific Cement and Aggregate Company until 1970s Lone Star Aggregates. Lone Star supplied gravel for local highway and interstate projects. The plant operated until the mid 1970s. Southern Pacific received approval to abandon the Fair Oaks branch on October 19, 1976.

In the early 1980s the Natomas Co. began planning development on remaining land along the river. During 1982 the community of “Gold River” was constructed. The Diamond Shamrock Corp acquired the Natomas Company, through a series of mergers the company ceased to exist. Today, the former site of the company of the rock crusher at Natomas is now the Lake Forest Industrial Park. The former Crusher No. 2 in Fair Oaks site is now part of the American River Parkway. Crusher No. 3 in Oroville was torn down and the site is now the site of the US Army National Guard station and neighboring Harrison Stadium.

2. Folsom Mining Case. Sacramento Union, Number 115, 16 June 1906

3. Natomas Development Buys Vineyard Co. Sacramento Union, Number 44, 7 October 1906.

4. Natomas Consolidation Incorporated. San Francisco Call, Volume 104, Number 178, 25 November 1908.

5. Request to close agency California Public Utilities Commission. 1915.

6. Gold Dredging By Electricity. GE Review Vol 14, No 1 Jan 1911..

7. Coast Rock Incorporated. Cement and Engineering News. Vol 32. No 5. Chicago, May, 1920. Pg 28.

Bibliography

Mines and Mineral Resources of the counties of El Dorado, Placer, Sacramento, Yuba

Report of the State Mineralogist Biennial Period 1915-1916 Page 143.

Aubury, Lewis E. Gold Dredging In California 1910. California State Mining Bureau, Bulletin No 57

“Who Is R.G. Hanford?” Town Talk, The Pacific Weekly Vol. XIX No. 960. San Francisco, January 21 1911.

Natomas Consolidated Company Timeline. Fair Oaks Historical Society (www.fairoakshistory.com).

"Reclaimation of dredge tailings, Folsom district". California Geology Vol XX No X June 1982 California Geologic Survey.

USGS Professional Paper, Tertiary Gravels of the Sierra Nevadas

Northern Electric's Stone Depots (http://www.wplives.org) Retrieved: February 20, 2016.

Martin, Al H"Natomas Consolidated of California" Mining Science, April 28 1910.

Converting Tailings To Commercial Products. AL. H. Martin. Mines and Methods, May 1912.

Reference Material Available Online:

Maps.

The Route of the Natomas Consolidated Company for Google Earth by Andrew Brandon.

Photographs.

Collected Natomas Consolidated Company Photographs.

Images collected from private collections, libraries and historical societies.

Ephemera.

The Garden District of California. Promotional pamphlet on the Natomas tract.

California State Library

Natomas News Number 1-3. Natomas Consolidated of California, Sacramento Calif.

Google Books

Articles.

|

Enormous Reclamation Project In Sacramento Valley. |

Natomas News 1911. Natomas Consolidated of California, Sacramento Calif.

California State Library

Natomas News March, 1913. Natomas Consolidated of California, Sacramento Calif. 1911.

California State Library

Natomas News May, 1913. Natomas Consolidated of California, Sacramento Calif. 1911.

California State Library

Reports.

Natomas Ditch System, Rhodes Ditch, West of Bidwell Street, north of U.S. Highway 50, Folsom, Sacramento County, CA.

Historic American Engineering Record.

Natomas Ditch System, Blue Ravine Segment, Juncture of Blue Ravine & Green Valley Roads, Folsom, Sacramento County, CA.

Historic American Engineering Record.

Keefe-McDerby Mine Ditch, East of East Bidwell Street between Clarksville Road & Highway 50, Folsom, Sacramento County, CA.

Historic American Engineering Record.

Reclamation District 1000, Northwest Sacramento County & southwest Sutter County, bisected by State Highway No. 99, Sacramento, Sacramento County, CA.

Historic American Engineering Record.